Project Background

Project Background

The Washington Post maintains a daily circulation of approximately 540,000 papers and is the largest of the Washington D.C. metropolitan area newspaper operations. However, many readers have opted to obtain news and information from various electronic media outlets and this has caused the current circulation rate to decrease over the past decade. According to the Newspaper Association of America, this is expected to continue to be the trend.

The Post is confronted with a continuous adjustment of the workforce level required to support a decreasing production rate. Inefficiencies occur as a larger workforce is employed to support the decreasing workload. A more optimal workforce could be determined by using a decision support tool that provides more real time responses to the impacts of workload assignments.

Project Objective and Scope

The purpose of this project is to provide a baseline simulation model in Arena to allow the Post to accomplish the production target goals while minimizing the labor resources and cost. The baseline Arena simulation model would only focus on the helper component of the work centers and model the material handling process within the Shipping and Receiving Department at the Post. Team PWP's main deliverable would be a flexible simulation model that can be used by the Post to make workforce planning decisions.

Project Work

Based on an in-depth study of the operational process at the warehouse of the Post and thorough discussions with the customer, Team PWP built a discrete event simulation model in Arena platform after comparing alternative options, given the nature and complexity of the problem. The model depicts the Post's overall process at their warehouses and it consists of the main module design used within the Arena model, and the basic processes occurring within the model.

Certain assumptions were made in the areas of model architecture, resources, arrival processes, service time distributions, and internal business logic. Team PWP first utilized the work from the previous group and then collected new data to perform process analysis on work centers quantitatively. Followed by process analysis on routes and operations, Team PWP obtained production data then performed input data analysis on statistics related to labor, routes and arrival process. Meanwhile, the model architecture was constructed in Arena. Once the model was complete, testing, evaluation, and sensitivity analysis indicated that it did in fact accurately model the system. Team PWP then conducted output analysis that demonstrated the capabilities of the model and how its statistics could be used to inform decision makings.

Project Results

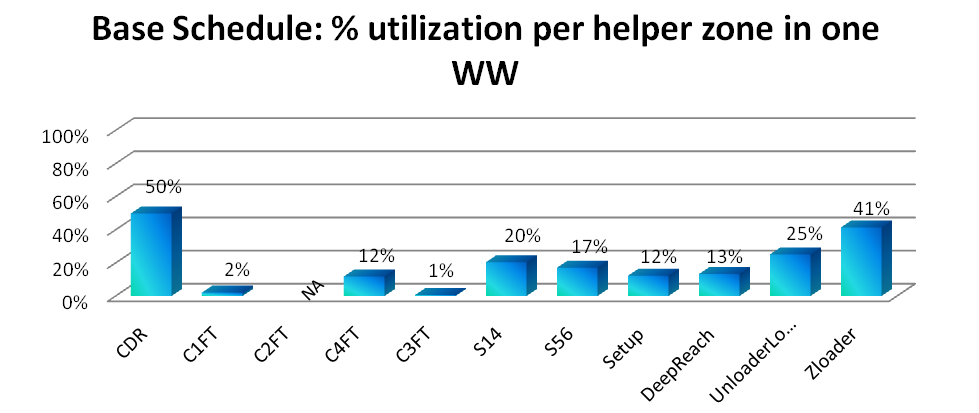

Team PWP performed output analysis by comparing the base labor markup schedule initially provided by the client and the modified labor markup schedule in term of helper moves, utilization and total production. The results indicated the modified labor markup schedule did increase productivity and save labor cost.

Team PWP came up with recommendations to improve the production cost savings at the warehouse by using the model.

Team PWP recommended the post to apply a modified labor markup schedule to the warehouse to save labor cost. A more efficient and optimized labor markup could be achieved by comparing the outputs after running the model against different labor markups. Utilizing the output analysis of the model for different schedule would help the Post to make labor markup decisions that meet production goals and reduce labor to cost the minimum. Furthermore, Team PWP suggested the post to develop stringent input data tracking mechanism to obtain accuracy in numeric values or distributions of input parameters. The values and distributions of input parameters of the model should be as realistic as possible for the model to produce accurate output.